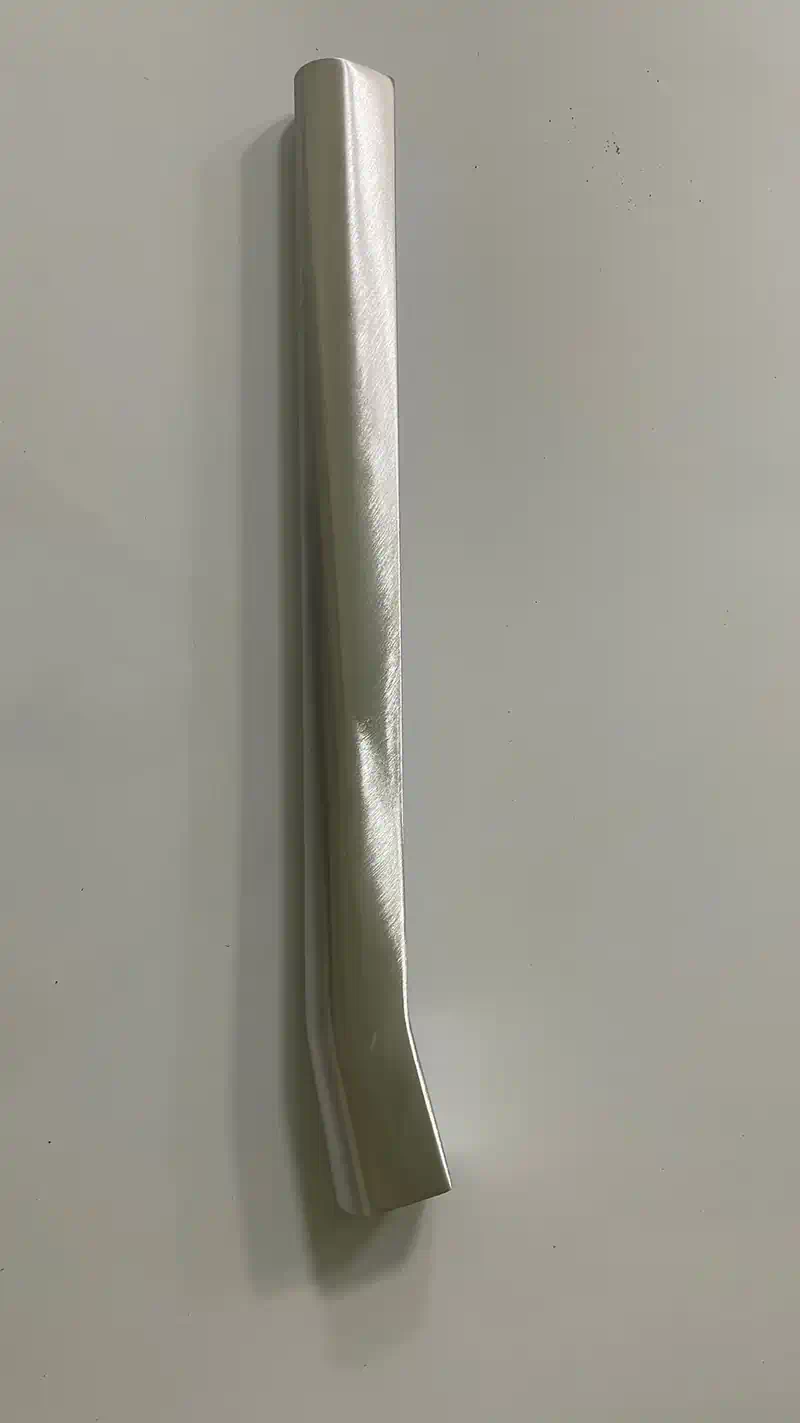

Bike Seat Tube

Bike Frame Seat Tube: Essential Guide for Cyclists and Designers

A bike frame seat tube is a crucial structural component connecting the bottom bracket area to the seatpost. Cyclists, bike manufacturers, and designers often ask: "How does the seat tube affect frame stiffness, energy transfer, and overall ride comfort?" The seat tube's geometry and material properties directly impact these factors, making its design and fabrication a key concern for anyone seeking optimal bike performance.

Manufacturing Process: Aluminum Tube Fabrication for Bike Seat Tubes

Thaishun uses advanced hydroforming technology to produce bike frame seat tubes, supporting both professional cyclists and casual riders who prioritize safety, comfort, and performance.

Key Steps in Manufacturing

- Hydroforming with Metal Plastic Deformation

- Tubes are shaped using hydraulic pressure, allowing precise control of cross-sectional geometry and wall thickness.

- This process creates lightweight yet strong seat tubes, ideal for modern bicycle frames.

- Double-End Drawing and Swaging

- These tube drawing methods enable fine dimension adjustments and custom profiles.

- Riders benefit from seat tubes that fit perfectly, enhancing comfort and safety.

- Profile Customization

- Complex contours and multi-angle bends support innovative bike designs.

- Aluminum tube fabrication allows for a wide range of frame geometries.

- Precision Machining

- Hydraulic presses ensure uniform wall thickness, eliminating weak points and improving structural integrity under heavy loads.

- Material Choice: 6061 Aluminum Alloy

- Known for its high strength-to-weight ratio and corrosion resistance.

- Wall thickness can be adjusted for durability without adding unnecessary weight.

Real-World Applications

- Cyclists seeking improved frame stiffness and efficient energy transfer.

- Bike designers needing seat tubes that support unique frame shapes.

- Manufacturers aiming for lightweight, durable aluminum tube fabrication in their products.

Why Choose Thaishun for Bike Frame Seat Tubes?

Thaishun’s expertise in aluminum tube fabrication and hydroforming ensures that every bike frame seat tube meets the demands of modern cycling. Their process supports precise integration with bike frames, contributing to safer, more comfortable rides and innovative bicycle designs.