Products

Professional Hydroforming Frame Tube Processing for Bicycles & E-Bikes

Looking for high-quality hydroforming aluminum frame tube solutions? We offer expert manufacturing and precision processing services to create lightweight, durable frames for bicycles and electric bikes. From material selection to custom shapes and finishes, we deliver exactly what your project needs.

Key Tube Processing Methods

1. Drawing

- Reduces tube diameter and maintains uniform wall thickness

- Improves surface smoothness and mechanical properties

- Enhances strength and dimensional accuracy

2. Bending

- Shapes tubes into precise angles for frames, handlebars, and forks

- Supports various curvature options for custom designs

- Used in bicycle frames, hand tools, and automotive exhaust pipes

3. Miter Cutting

- Creates angled tube ends for seamless welding and assembly

- Essential for frame construction and mechanical parts

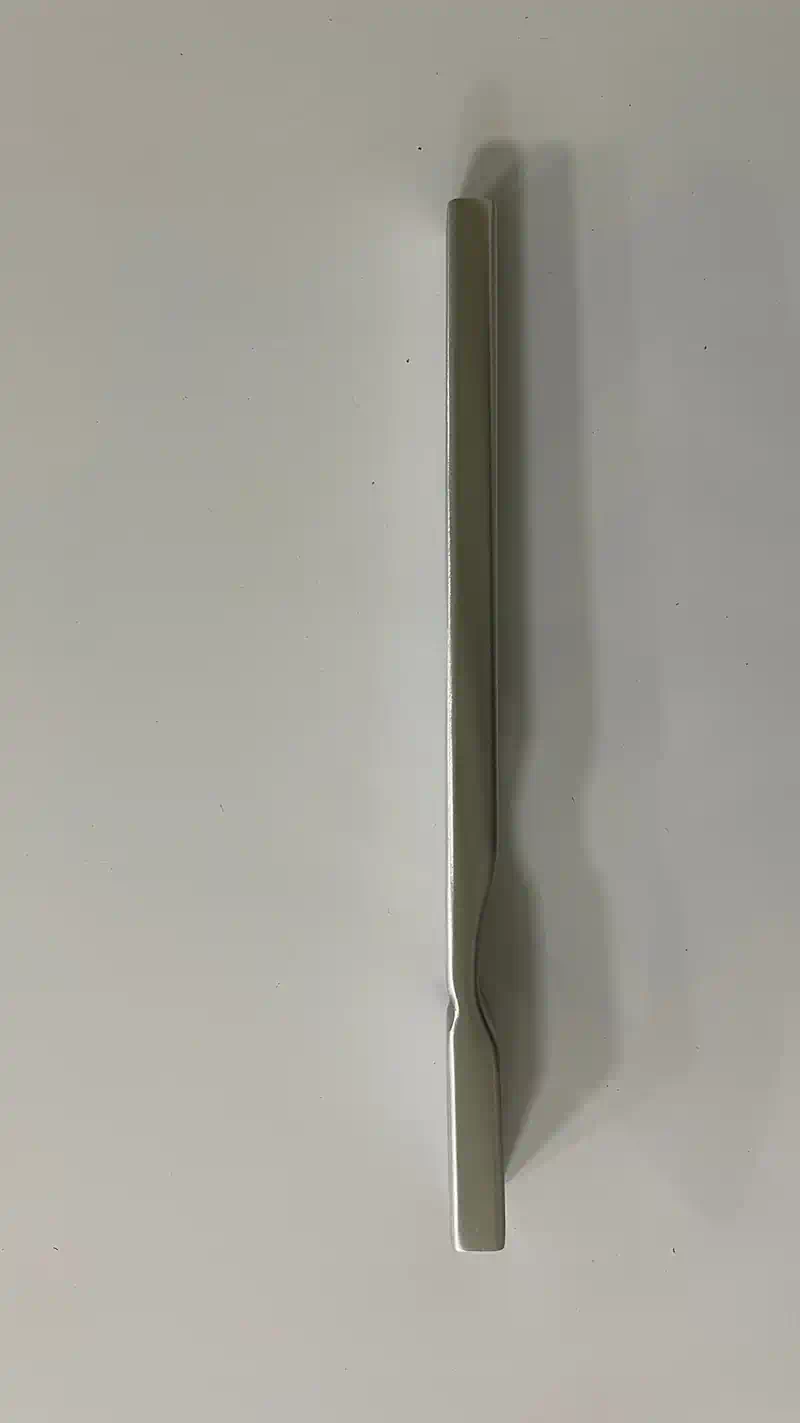

4. Fluting

- Adds grooves or patterns to tube surfaces

- Increases friction, reduces weight, and enhances aesthetics

- Applied to sports equipment, bike frames, and premium furniture

5. Stamping

- Uses molds and press machines to form holes, depressions, or structural features

- Widely used in automotive, mechanical, and architectural components

6. Hydroforming

- Employs high-pressure fluid to shape tubes into complex geometries

- Results in lighter, stronger, and more precise products

- Ideal for bicycle components, automotive parts, and aerospace applications

Real-World Applications

- Top tubes, seat tubes, down tubes, rear forks, handlebars, and battery boxes for bicycles and e-bikes

- Custom tube processing for sports equipment and industrial parts

Why Choose Thai Shun Industrial Co., Ltd for Hydroforming Tube Processing?

- Extensive experience with aluminum alloy tube processing

- Advanced equipment for drawing, bending, hydroforming, stamping, and more

- Ability to meet specific client requirements for design, strength, and aesthetics

- Products used by bicycle brands, e-bike manufacturers, and industrial clients worldwide

- If you need expert guidance or custom tube processing for your next project, Thai Shun Industrial Co., Ltd provides a full range of aluminum frame tube services for bicycles, e-bikes, and more.